Customization

What Is Product Customization?

Customers today expect more than just a product—they want something that feels personal. Offering tailored options helps you meet these expectations while creating a unique shopping experience. Customization doesn’t just make your customers happy; it also drives your business forward. You can boost sales, build stronger customer loyalty, and stand out in a crowded market. By focusing on personalized solutions, you’ll create deeper connections with your audience and unlock new growth opportunities. Customization refers to the process of tailoring a product to meet your specific needs or preferences in your market. This can involve altering the appearance, functionality, packaging or delivery method to create a more personalized and satisfying user experience.

Hrefine

For connectors, we offer different plating options for shells and pins, different colors, styles for tails and rings.

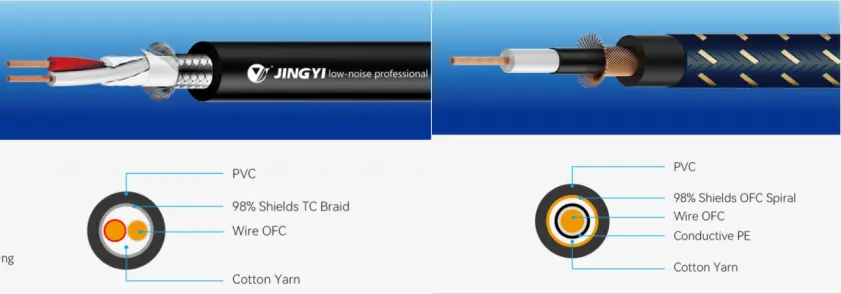

For cables, we offer different cable specifications and options of outside cotton braided patterns.

For stands, we think from consumers’ point of views. We offer different style of parts and different lengths of stands upon your request.

Why Does Customization Matter?

• Customization enhances customer satisfaction by allowing individuals to create products that reflect their personal preferences.

• Offering personalized options can significantly boost sales, as customers are often willing to pay more for unique items.

• Building strong customer loyalty is easier when you show that you value individuality through tailored products.

• In a competitive market, customization sets your business apart and positions you as a leader in your industry.

• Utilizing the right technology and tools is essential for a seamless customization process that enhances the customer experience.

• Regularly gather and analyze customer feedback to continuously improve your customization offerings and meet evolving demands.

Lessons Learned from Real Cases

• Make Customization Easy: Like Amazon Custom, simplify the process for your customers. Use tools that allow them to visualize their personalized products before buying.

• Focus on Uniqueness: Follow Etsy sellers by offering options that stand out. Highlight the individuality of your products to attract customers seeking something special.

• Build Trust Through Transparency: Show customers exactly what they’ll receive. Clear previews and detailed descriptions reduce uncertainty and increase confidence in your brand.

• Engage with Your Audience: Personalization is more than just a feature—it’s a way to connect. Listen to your customers’ needs and preferences to create products they’ll love.

Why Customers Value Customized Products?

Customers love products that feel like they were made just for them. Personalization gives them a sense of ownership and satisfaction. It’s not just about the product itself—it’s about the emotional connection they form with it. When they can customize something, they feel heard and understood. This makes their shopping experience more enjoyable and memorable. Additionally, many people are willing to pay more for customized items, which shows how much they value this option. By offering customization, you’re meeting their expectations and creating a stronger bond with your audience.

• Showcase Your Brand’s Personality: Personalized products reflect your brand’s unique qualities. They help you stand out and leave a memorable impression.

• Foster Emotional Connections: When customers feel involved in creating their products, they form a deeper bond with your brand.

• Encourage Word-of-Mouth Marketing: Satisfied customers often share their customized items with friends and family, spreading awareness about your business.

• Build Long-Term Loyalty: Personalization makes customers feel valued, increasing the likelihood they’ll return for future purchases.

In today’s competitive market, strong relationships are key to success. Customization gives you the tools to connect with your audience on a deeper level. By focusing on their individuality, you create a brand that people trust and love.

Product customization has become a game-changer for businesses aiming to grow and thrive. It empowers you to meet customer expectations while creating unique experiences that drive loyalty and repeat purchases. By offering personalized options, you can boost sales, strengthen your brand, and gain a competitive edge in the market. Now is the time to take action. Start exploring how customization can fit into your business strategy and begin building deeper connections with your audience today.